Standalone Solar PV systems are prevalent in places where the grid is either absent or has very poor reliability. These systems have a huge application in rural, remote, isolated and semi- urban areas which have no or limited access to power. The consumer sets up the solar rooftop system with the intention of utilizing all the power generated by the system onsite. The value proposition from these rooftop systems comes from either replacing the costlier diesel generators or providing grid quality electricity services. As the generation and consumption profiles vary significantly in these kinds of systems, storage systems like batteries need to be integrated with these systems.

The solar PV modules generate power in the DC form and the batteries store the energy in the DC form, therefore, it is easy to operate DC loads in the solar PV systems. But most of the loads around us use AC power. Therefore, we use additional system component, Inverter which converts DC power into AC power. This system is a universal system in which any type of AC or DC load can be operated. All kinds of load like fan, computer, TV, LEDs, tube lights, CFLs etc. can be operated using this type of system configuration.

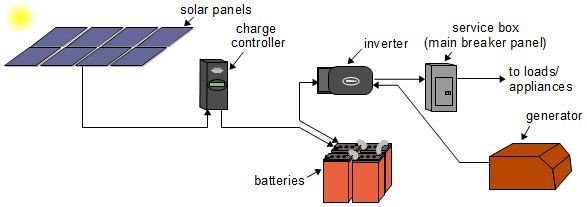

In the standalone PV system, energy is generated by solar PV modules. It is stored in batteries and then supplied to the load when required. Therefore, the flow of energy is from module to battery and then to load through power converters. The system design proceeds in the reverse direction than that of energy flow. Thus, first the loads and their requirements (power, hours of operation, energy requirement, etc.) are identified and then sizing is done. It is then followed by the battery sizing, power converter sizing, charge controller and MPPT circuit design followed

System Components:

The standalone solar PV Power Plant comprises of the following major components and services. The components, assemblies, sub-assemblies are selected with stringent criterion like long life, highest reliability, minimum maintenance etc. All the systems and sub systems are supported by comprehensive application notes & documentation.

- Solar PV modules

- Module mounting structure

- Power Conditioning unit (with smart Charge controller & Inverter)

- DC/AC cables, junction & combiner boxes & cable trenches

- Control panels

- Plant monitoring systems

Solar PV modules:

We use two major types Solar PV module i.e 1. Crystalline Silicon (c-Si) and 2. Thin film modules.

Crystalline Silicon Solar PV module: Crystalline Silicon (c- Si) is a term used for the crystalline forms of silicon encompassing multi- crystalline silicon (multi-Si/ Poly-Si) and mono- crystalline silicon (mono-Si), the two dominant semiconducting materials used in photovoltaic technology for the production of solar cells, that are assembled into a solar panel and part of a photovoltaic system to generate solar power from sunlight.

Thin Film Module: A Thin Film solar cell (TFSC), also called a Thin Film photovoltaic cell (TFPC), is a second-generation solar cell that is made by depositing one or more thin layers, or thin film of photovoltaic material on a substrate, such as glass, plastic or metal. Thin film solar cells are commercially used in several technologies, including cadmium telluride (CdTe), Copper Indium Gallium- di-selenide (CIGS), and amorphous and other thin film silicon (a-Si, TF-Si) etc.

Film thickness varies from a few nano-meters (nm) to tens of micro-meters much thinner than thin film’s rival technology, the conventional, first generation crystalline silicon solar cell (c-Si), that uses silicon wafers of up to 200 micro meters. This allows thin film cells to be flexible, lower in weight, and have less drag. It is used in building integrated photovoltaic, and as semi- transparent photovoltaic glazing material that can be laminated onto windows. Other commercial applications use rigid thin film solar panels (sandwiched between two panes of glass) in some of the world’s largest photovoltaic power stations.

Power Conditioning Unit:

Power conditioning unit comprising of high efficiency solar charge controller (to charge the battery at the maximum power available from the solar panel) and a high efficiency Sine-Wave inverter, to run equipments like computers, machineries, fans, tubes, TVs etc.

A Charge controller is a piece of electronics that’s placed between the PV array and the battery bank. The primary function of the charge controller is to control the flow of charge from the battery and to the battery. They protect the battery by preventing over-charge or deep- discharge of batteries to preserve their life and performance.

The following two types charge controllers are mostly used are-

- Pulse width modulation (PWM) charge controller or standard charge controller. These charge controllers have same nominal voltage across battery bank and PV array.

- Maximum Power Point Tracking (MPPT) charge controller. These charge controllers can have different voltage across battery bank and PV array and operate at the maximum power point tracking of the PV panel. MPPT charge controller allows us to have a solar panel array with a much higher voltage than your battery bank voltage.

Standalone inverters are not designed to interact with the utility and work by supplying power to loads. These require a stable voltage source of power, typically a battery bank, to keep the inverter running. A PV system using this inverter requires more components and is generally more complicated, but it allows the user to have backup power for times when the utility goes out. Battery- based inverters use a PV array and charge controller on DC side and connect to utility on the AC side. During normal operation in a stand-alone system, the battery-based inverter accepts DC power from the battery bank, turns it into AC power, and delivers that AC power to the loads connected in the main distribution panel.

Batteries:

Batteries, as electrical energy storage medium, are very important and delicate part of standalone solar PV systems. Batteries used in this system store the energy from solar array and provide power draw for the loads during nighttime or at any specific time (cloudy weather, or if a number of loads are running during the day).

Off grid standalone solar PV systems use true deep- cycle rechargeable batteries. These are designed for the slow, steady and deep discharge suitable for powering household or workshop loads, such as lights, tools, and appliances.

Below are some of main types of deep cycle batteries used in solar systems: lead-acid, nickel- iron and lithium ion.

Lead- acid batteries are the most commonly used type by far, due to their balance of performance, relatively long life, and reasonably low cost. Flooded lead- acid batteries tend to be the cheapest, but they need to be topped up with distilled water on a regular basis. Sealed lead- acid batteries wont leaked when tipped and are essentially maintenance free. They come in two types: absorbed glass mat (AGM) and Gel.

Nickel- iron (NiFe) batteries are made with potassium electrolyte that is less hazardous material than electrolytes in other battery types. These batteries are robust and durable and can last many times longer than lead- acid batteries, but they have a relatively low storage capacity for their size as well as a high rate of self- discharge and low rate of efficiency. They are also more expensive and are much less available then standard batteries. These batteries are favoured for their long life and relative immunity to overcharging and over discharging, it for little else.

Any battery requiring maintenance, including FLA and NiFe batteries, needs ventilation to expel explosive hydrogen gas produced by the electrolysis of water inside the battery. Enclosures for these batteries must include means for ventilation and large banks may need an explosion- proof exhaust fan to adequately ventilate the gas generated.

Lithium batteries for solar systems are in the same family as batteries used for cell phones, laptops, and electric vehicles. They offer many advantages over lead acid batteries but are significantly more expensive. Lithium batteries are about 1/3 the size and ½ the weight of lead acid batteries with comparable storage capacity, making lithium particularly attractive for RVs and other portable applications where space and weight are important considerations. Lithium offers about twice the battery life of lead acid, and lithium batteries can be discharged to 80% with no significant effect on longevity. That means few batteries to buy and less frequent replacement. Lithium storage requires a sophisticated battery management system (BMS), which adds further to the overall cost. For large systems, lithium storage may be available as part of a manufactured system that couples batteries with the proper charging mechanism for ease-of-installation and to promote safety by ensuring only qualified individuals will work with these highly technical components.

Module mounting structure:

Module mounting structures are used to mount the PV modules in particular orientation to collect maximum sunlight. The two main types of PV mounting systems in use are roof mounted and ground mounted. The design of module mounting structure should consider local site conditions such wind speed, rain fall & temperature etc. it is important that structure galvanization should be sufficient to protect it from corrosion.

DC & AC Cables:

DC cables conduct solar electricity from PV array to the string junction box and from string junction box to the battery and to the inverter. They are to carry the required current along with necessary safety margins and also limit the voltage drop (resistance losses). As a general practice, the DC wiring should not cause more than 2% power loss in the system. The DC cables used in solar strings use specialized connectors. These connectors are characterized by their electrical properties, mechanical properties and weather resistance. As these connectors are usually installed outdoors, they should be IP67 rated UV and fire resistant with typical operating temperature.

AC cables carry the AC power of the PV system from the Inverter to the main distribution panel. It is to be selected critically to ensure safety as well as minimize power loss. As a general practice, AC wiring loss of PV system should not exceed 2%.

DC Distribution box (DCDB):

The string combiner box also called as Array Junction box (AJB) or PV Generator junction box, combines multiple DC strings in parallel. The circuit in it is used to connect SPV array and battery bank to the inverter. The DCDB commonly houses the input overcurrent protection fuse assemblies for several strings, as well as the combined bus of these inputs into a single main output. Combiner box may also house several other components for the site, such as DC disconnect, surge protective devices and in some cases, string monitoring hardware.

AC Distribution Box (ACDB):

ACDB should be placed close to the inverter immediately after the inverter. The load at the client’s premises will be powered by Inverter AC output under all conditions. The ACDB should also contain Miniature Circuit Breakers to disconnect incoming and outgoing AC connections, Residual Current Circuit Breakers (RCCB) and SPD.

Grounding/ Earth pit & Lightening arrestor:

The main reason for doing earthing in electrical network is for the safety. When all metallic parts in electrical equipments are grounded then if the insulation inside the equipment fails there are no dangerous voltages present in the equipment case. If the live wire touches the grounded case then the circuit is effectively shorted and fuse will immediately blow. When the fuse is blown the dangerous voltages are away.

A lightening arrestor is a device used on electrical power systems and telecommunication systems to protect the insulation and conductors of the system from damaging effects of lightening. The typical lightening arrestor has a high voltage terminal and a ground terminal.

Monitoring:

Meters or data loggers and remote monitoring can be provided.

Solar Photo Voltaic off-grid system can be used for following applications.

- Solar Home & Commercial Light System

- Solar Street Lighting

- Solar Water Pumps

- Solar Rural electrification

- Solar lantern, Solar DC home light systems (2 LED bulbs of 3W each, mobile charging port etc)

HYBRID POWER

The Solar Wind Hybrid Power Generation system is the combination of Micro Windmill and Solar Photo Voltaic technologies offers several advantages over either single system. In most of the areas of India, wind speeds are low in the winter season when the sun shines bright, and the wind is strong in the rainy season when less sunlight is available. And in summer season both wind as well as sun light is brighter, we can harvest best of wind and solar energy. Because the peak operating times for wind and solar systems occur at different times of the day and year, hybrid systems are more likely to produce power when you need it.